Experience ultimate durability: Make the future of industry cleaner and stronger with PEEK coatings,

What Is PEEK Coating?

PEEK(Poly Ether Ether Ketone) is a super engineering plastic resin that has various resistances. PEEK coating is created by processing PEEK resin into fine powder and dispersing it in water or special solvents. This dispersion is applied to a substrate and then baked at high temperatures to form a thin film with the excellent properties of PEEK resin. This method allows for uniform coating on parts with complex shapes, achieving high-performance surface treatment with heat resistance, chemical resistance, and wear resistance.

allive® PEEKcoating, exclusively distributed by Global Code, is developed by Zenith, a Korean company specializing in the development and production of special coatings. It is currently being widely adopted in various industries such as food, medical, automotive, aerospace, and electronic components.

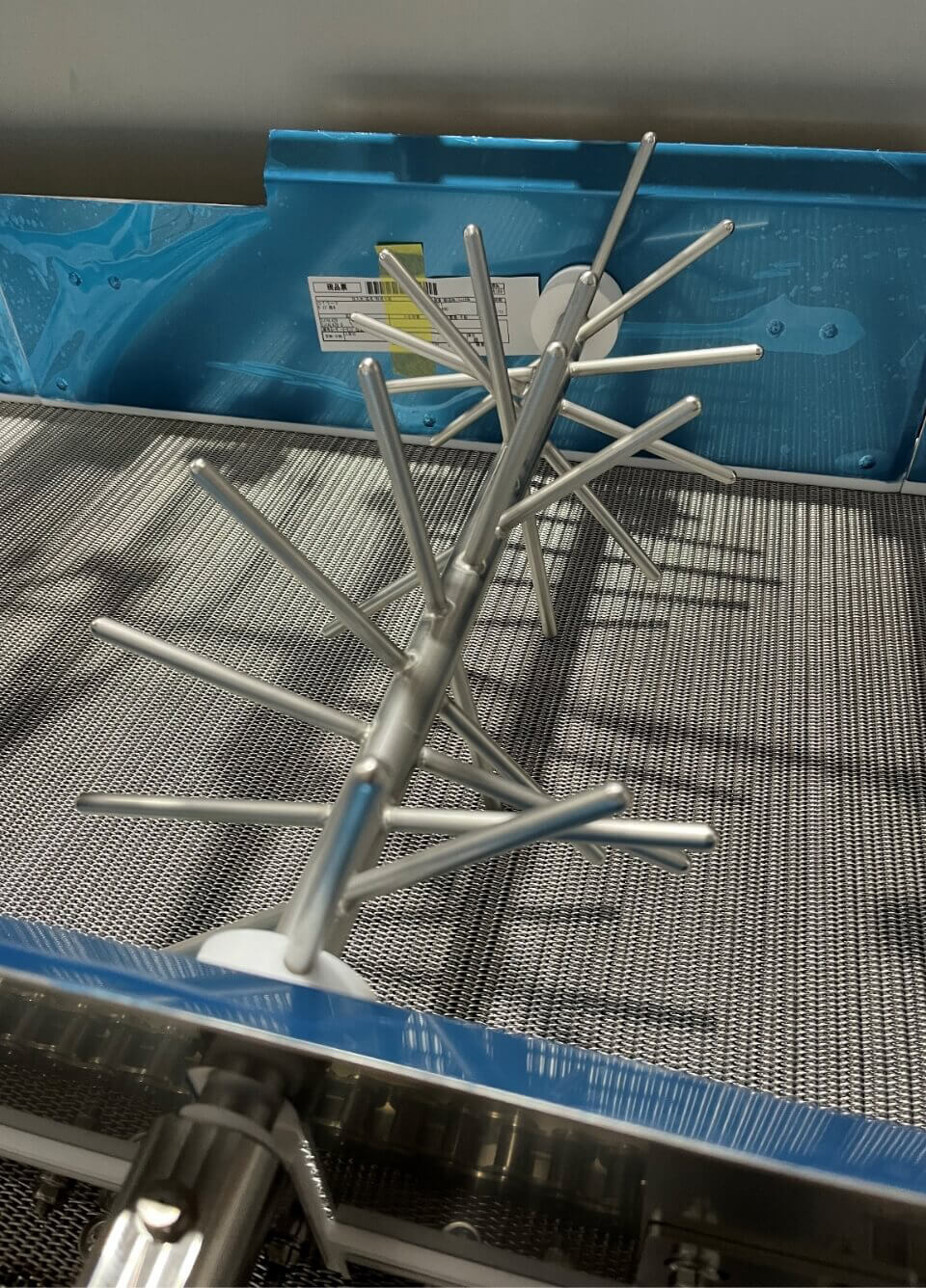

▲Photo: PEEK coated test piececontact us to request them.

- Our Product Lineup

-

- 100% PEEK (Fluorine-free): Extremely high wear and chemical resistance

- PEEK with lass than 20% florine: Extremely high non-stick properties

Why PEEK Coating?

Mechanical Durability Features

Among the many types of coatings—such as silicone, fluorine, and ceramic—PEEK coating stands out for its exceptional properties:

Abrasion ResistanceChemical ResistanceHeat Resistance

Electrical InsulationNon-StickLow Friction

For example, when you apply PEEK coating to your molds, it can significantly extend the mold's service life and reduce recoating frequency.

This simultaneously boosts production efficiency and cuts costs, while offering various other benefits. Its strong adhesion to stainless steel is particularly revolutionary in food manufacturing plants.

PFAS Regulation

“PFAS,” a collective term for organic fluorinated compounds, is indispensable in consumer goods, industrial products, and manufacturing. However, PFAS does not break down easily in nature, raising concerns about environmental pollution and potential health impacts. As a result, regulations are being tightened, particularly in the EU and the United States.

In light of this, PEEK coating is gaining attention as an eco-friendly alternative. By preparing to transition to PEEK coatings now—anticipating PFAS regulations, which are expected to take effect by 2028—you can mitigate future risks and build a sustainable production system.

Comparison Table

The superiority of PEEK coating becomes clear when compared with other major coating materials.

It outperforms alternatives in abrasion resistance, chemical resistance, heat resistance, and electrical insulation. In terms of non-stick properties, it demonstrates high performance close to fluorine coatings, and in many usage environments, its excellent abrasion resistance helps it last longer.

You can see these advantages more concretely in the comparison table below.

| PEEK AP105 | Fluorine | Ceramic | Silicone | |

|---|---|---|---|---|

| Abrasion Resistance | ◎ | ◯ | △ | △ |

| Non Stickiness | ◯ | ◎ | △ | ◯ |

| Electrical Insulation | ◎ | ◯ | △ | ◯ |

| Chemical Resistance | ◎ | ◯ | △ | ◯ |

| Continuous Use Temperature | 260℃ | 260℃ | 400℃ | 150~200℃ |

| Hardness | 9H | H~3H | 9H or higher | H~3H |

| Adhesion | ◎ | △ | ◯ | ◯ |

| Presence of Pinholes | No | Yes | Yes | Yes |

*Please swipe sideways to see the table.

◎…Very good

〇…Good

△…Not good

Types and Characteristics of PEEK Coating

Our PEEK coating products are designed to deliver optimal functionality for each application. AP105 maximizes adhesion to the substrate as a primer (base coat). Then, you can choose among three types of topcoats—AT135 (eco-friendly, fluorine-free), AT105, or AT125 (PEEK coating with less than 20% fluoropolymer)—and then apply and bake them over the base to achieve high performance.

Features of Each Coating

The following table summarizes the characteristics of the base coat AP105 and the topcoats AT135, AT105, and AT125:

| AP105 | AT135 | AT105 | AT125 | |

|---|---|---|---|---|

| Type | Base | Top | Top | Top |

| Particle (µm) | 20 | 20 | 20 | 20 |

| Specific Gravity | 1.3 | 1.3 | 1.3 | 1.3 |

| Color | Black | Black | Metallic Ivory | Ivory |

| Hardness (Pencil Hardness) | 9H | 9H | 6H | 6H |

| Thickness(μm) | 20~30 | 15~30 | 15~25 | 15~25 |

| Drying & Baking Temperature (Based on Metal Temperature) |

380~390℃ X 5~10min Tmax<400℃ |

380~390℃ X 5~10min Tmax<400℃ |

400~410℃ X 10~15min Tmax<410℃ |

400~410℃ X 10~15min Tmax<410℃ |

| Continuous Use Temperature(℃) | 260℃ | 260℃ | 260℃ | 260℃ |

| PFAS-Free Percentage | Fluorine Free | Fluorine Free | Fluorine less than 20% | Fluorine less than 20% |

*Please swipe sideways to see the table.

Comparison of Resistance When Each Topcoat Is Applied Over AP105

The following chart outlines how resistance improves when each topcoat is applied and baked over the base coat. This two-layer structure allows each property to be maximized.

-

AP105

-

AP105 + AT135

-

AP105 + AT105

-

AP105 + AT125

Examples of PEEK Coating Application

The benefits of PEEK coating have been demonstrated across various industries.

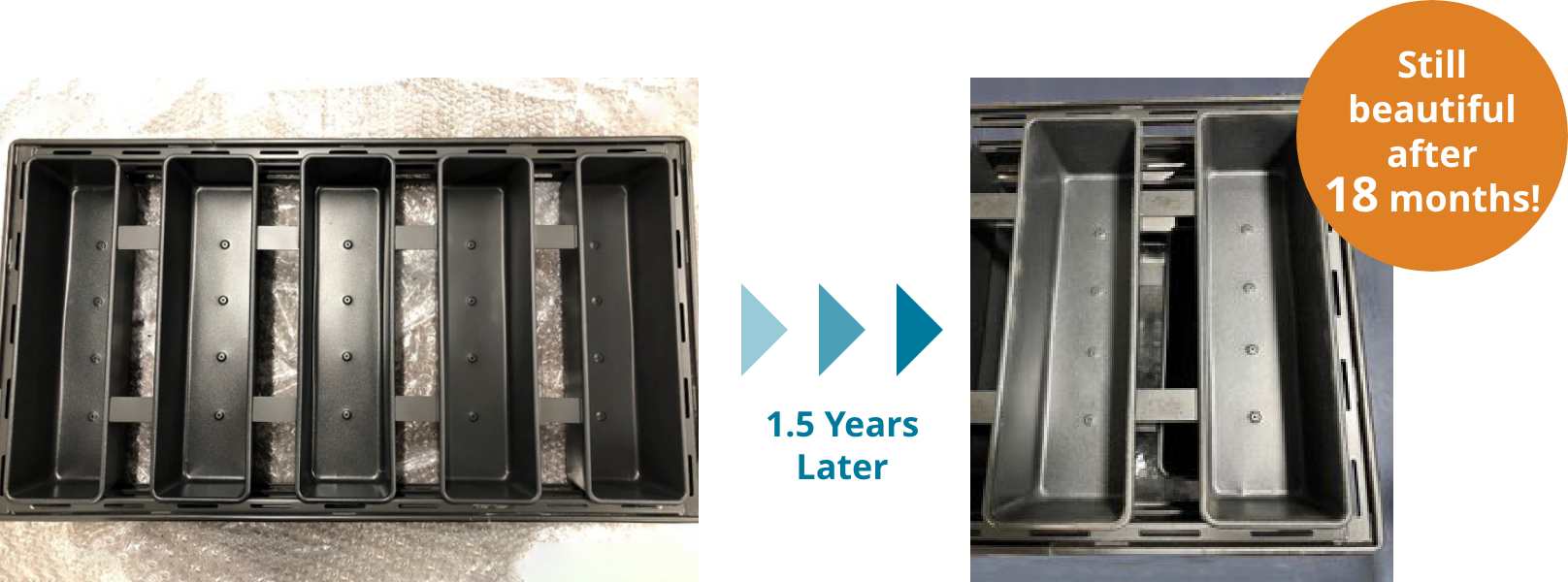

[Bread Loaf Mold]

Innovation in Bread Production. Achieve next-level mass production with long-lasting, easy-release coating.

It solved the frequent recoating problems and release issues. After 18 months of testing, there was no peeling of the coating, and no problems with release of the bread. It also received praise for improving the yield of bread. The factory manager commented, “This coating is an innovation for the bread industry!” About 4,000 units are scheduled for order in 2024.

Applicable to use for roll bread pans and flat pans.

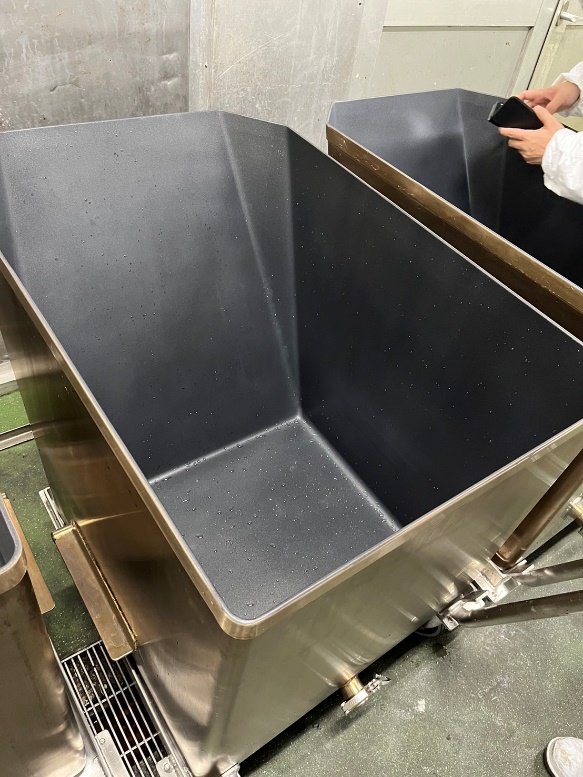

[Food Production Line]

Achieve 4x the Durability—Reinventing the Production Line. An Efficiency Revolution in Food Manufacturing!

We successfully reduced sticking with items like frozen udon, potato salad, and minced chicken. This has significantly shortened cleaning times for equipment and confirmed excellent adhesion to stainless steel. With improved coating durability, the fluorine coating previously used required recoating every two weeks, but PEEK coating has lasted over two months. As a result, users have told us, “Thank you for a product that gives us hope!”

It can be applied to any substrate, including stainless steel or titanium wagons, hoppers, mixers, shooters, and smoke hangers.

*Click to enlarge the image.

[Cooking Appliances]

Proven Safety and Durability Over 20 Years—From Rice Cookers to the Future of Kitchens

We have about 20 years of experience applying PEEK coating to the inner pots of rice cookers in the Japan market. We address concerns such as peeling fluorine coatings and PFAS regulations with over 20 years of proven performance and FDA-approved food safety.

For current frying pans that use PEEK coating, there is still a sticking issue, and we are developing a product that can solve this problem.

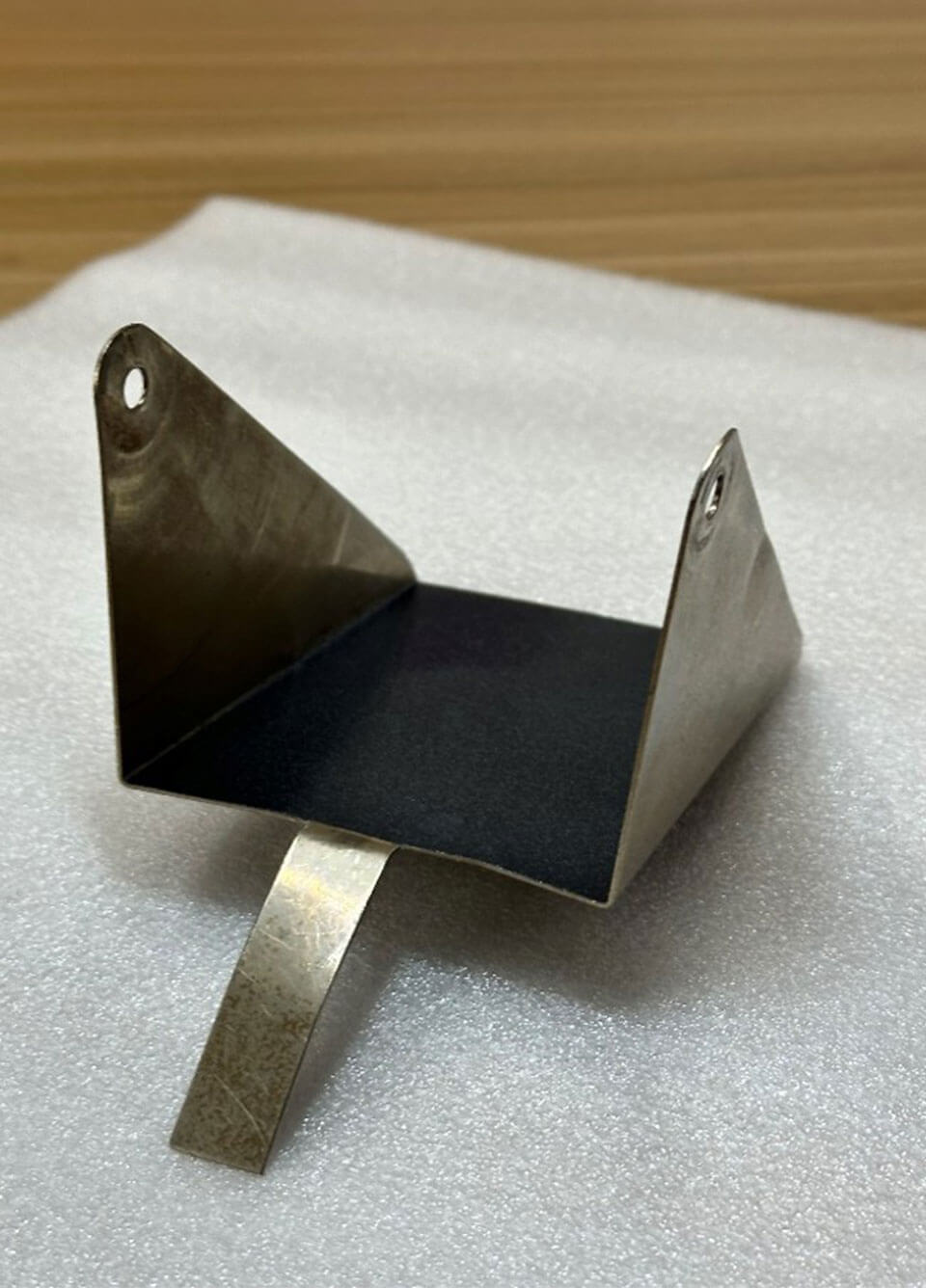

[Automotive Motor Mold]

Achieve Sustainable Mold Manufacturing: Release-Agent-Free, High Durability—A New Standard in Environmental and Operational Efficiency-

*Images are for illustration purposes only

*Images are for illustration purposes only

-

Applications for sheet molds and painting jigs required eliminating release agents due to environmental concerns and resistance to alkaline strippers. By introducing PEEK coating, both reduced environmental impact and improved work efficiency were achieved.

-

*Images are for illustration purposes only

*Images are for illustration purposes only

-

[Work Glove Mold]

No More Abrasion or Corrosion. Take Durability to the Next Level and Reduce Maintenance Frequency!

This end-user previously applied a fluorine coating on the mold surface, but abrasion from glove production and

chemicals used in rubber processing caused coating deterioration and mold corrosion.

With PEEK coating's superior abrasion and chemical resistance (no pinholes), the interval between recoatings can

potentially be extended.

[Nonwoven Stainless Guide Roll]

From Just One Month to Over Half a Year: PEEK Coating Transforms Production Lines-

Before Coating

Before Coating

-

Before Coating

Before Coating

This end-user used to apply a thick fluorine coating for non-stick purpose, but it only lasted one month.

It has already been six months since switching to PEEK coating, and there have been no issues with the film.

-

Stainless Steel Guide Roll – Before Coating

Stainless Steel Guide Roll – Before Coating

-

Stainless Steel Guide Roll – After Coating

Stainless Steel Guide Roll – After Coating

Japan Food Health Certificate・FDA Certifications

Just one year since the start of our promotion, PEEK coating has earned high praise from users across a wide range of industries, and multiple companies have already decided to move into mass production.

As an innovative solution that meets diverse industrial needs, PEEK coating holds significant market potential.

We invite you to consult with us here to find out how PEEK coating can contribute to innovating your products.

Exclusive Distributor of ZENITH

| Company Name: | GLOBAL CORD LTD. |

|---|---|

| Address: | GLOBAL BUILDING 2F, 1-12-3 Awaza, Nishi-ku, Osaka 550-0011, JAPAN |

| TEL | +81-6-6567-8577 |

| Business Description: | Wholesale, sales, and trade of various electrical/electronic components, PEEK coatings, fluorine coatings, steel wire materials, etc. |

| Established: | March 23, 2015 |

| Capital: | 3 million yen |

| Annual Sales: | 5 billion yen (Fiscal Year ending October 2024) |

| Representative: | President & CEO, Kenkichi Inoue |